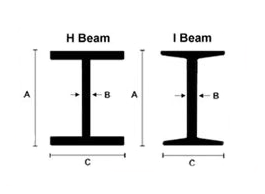

Lets start with the most widely used beam for structural steel. W-Beams, so called because they are technically known as Wide-Flange Beams, come in a wide variety of size from 4” tall to 44” tall. Note: the size description of the W-beams are always listed as height of beam x lbs. per foot of beam (ex. 8×31 is 8” tall with a load capacity of 31 pounds per foot). These beams are also sometimes referred to as H-beams because on their side, the cross section looks like a capital H. When it comes to the actual structure and shape of the W-beam, there are two components two key components to the shape; there is the web of the beam, and the flanges of the beam. The flanges are the top and bottom (horizontal) members of the structure, while the web is the vertical member that holds the two flanges together. Each of the three members that make up the beam are flat and straight, with radius inside corners where each connects. These beams are commonly used in residential and commercial construction to span between columns and help support the load of the building. To find out exactly what size W-beam is needed for your project, an engineer must run calculations to find the moment of inertia, which coincides with a certain beam size. For every beam depth, which generally climbs in 2” increments, there are several variations, which carry different loads, or pounds per foot.

Lets start with the most widely used beam for structural steel. W-Beams, so called because they are technically known as Wide-Flange Beams, come in a wide variety of size from 4” tall to 44” tall. Note: the size description of the W-beams are always listed as height of beam x lbs. per foot of beam (ex. 8×31 is 8” tall with a load capacity of 31 pounds per foot). These beams are also sometimes referred to as H-beams because on their side, the cross section looks like a capital H. When it comes to the actual structure and shape of the W-beam, there are two components two key components to the shape; there is the web of the beam, and the flanges of the beam. The flanges are the top and bottom (horizontal) members of the structure, while the web is the vertical member that holds the two flanges together. Each of the three members that make up the beam are flat and straight, with radius inside corners where each connects. These beams are commonly used in residential and commercial construction to span between columns and help support the load of the building. To find out exactly what size W-beam is needed for your project, an engineer must run calculations to find the moment of inertia, which coincides with a certain beam size. For every beam depth, which generally climbs in 2” increments, there are several variations, which carry different loads, or pounds per foot.

Now, I know you’re thinking….Wow! That was more information than I needed! But, next time you are remodeling your house, building a garage or are the part of a new build, you can be more aware of the structure that is holding your project together. But what about I-beams? Oh yeah…..almost forgot.

So if the steel beams that everyone mistakenly calls wide-flange beams by the wrong name, I-beams, then what in the heck is an I-beam? I-beams are rarely used in modern construction anymore unless the building is being retrofitted. The main reason for the W-beams success is the way these two beams are milled. Essentially, I-beams are made by milling, or rolling, steel which means that the size of the beam is restricted to the capacity of the milling equipment. W-beams on the other hand are built up, which allows the mill to make them any size required. When it comes to the structure of the I-beam, the web is often much thicker than the web of those on W-beams, and is also much thicker than the flange on the I-beam. On W-beams, the flanges are generally thicker than the web. Another key feature of the I-beam is that the flanges are tapered and the web stands much taller than the width of the flanges. For these two reasons, the cut section quite literally looks like a capital letter “I”. The I-beam is generally much lighter in weight, which makes it easier to handle in some situations.

So if the steel beams that everyone mistakenly calls wide-flange beams by the wrong name, I-beams, then what in the heck is an I-beam? I-beams are rarely used in modern construction anymore unless the building is being retrofitted. The main reason for the W-beams success is the way these two beams are milled. Essentially, I-beams are made by milling, or rolling, steel which means that the size of the beam is restricted to the capacity of the milling equipment. W-beams on the other hand are built up, which allows the mill to make them any size required. When it comes to the structure of the I-beam, the web is often much thicker than the web of those on W-beams, and is also much thicker than the flange on the I-beam. On W-beams, the flanges are generally thicker than the web. Another key feature of the I-beam is that the flanges are tapered and the web stands much taller than the width of the flanges. For these two reasons, the cut section quite literally looks like a capital letter “I”. The I-beam is generally much lighter in weight, which makes it easier to handle in some situations.

So to wrap up this rant….generally, it is always best to speak with an engineer first, before trying to size your steel beam, but chances are if you are looking for a structural steel beam, you are looking for a wide-flange beam, or a W-beam….not an I-beam.